Simple screening of 3D resins

Simple screening of 3D resins properties for selecting the right 3D resin before printing your final prints

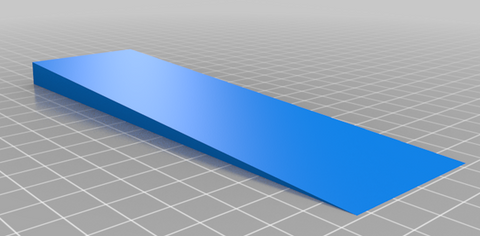

- print directly a wedge with your chosen 3D resin

- adjust the wedge size to the total surface of your prints on the build platform

- print the wedge directly on the build platform. If it breaks during its separation with the spatula due to excessive adhesion to the platform, then print it with supports or sidewards to facilitate its removal

- use the printed wedge to screen the peeling or separation force, the flexibility/rigidity as well as the fracture resistance of the material

- position the wedge vertically and force it sidewards gently and firmly to measure the thickness at which the wedge does not deform or bend at all. This value in mm will give an indication of the thickness threshold at which the material becomes rigid. Below this thickness threshold the material is flexible

- position again the wedge vertically and force it sidewards strongly and firmly until it breaks to measure the maximum thickness at which the tip of the wedge breaks. This value in mm will give an indication of the toughness of the material. The lower the thickness of the remaining wedge the tougher the material!!

- design a thinner or thicker, a shorter or longer wedge depending on your needs, which will depend on the relative size of your printed parts

- relatively thinner and longer wegdes are ideal for small size works

- relatively thicker and shorter wedges are good enough for large size works

- relatively longer wedges help to identify smaller differences in rigidity/flexibility and in toughness since the maximum thickness, at which the tip of the wedge deforms and breaks upon pressure, can be measured with more precision

- print a wedge horizontally, without supports in your printer

- depending on your initial results, test or not a more rigid or flexible resin, taking into account your required flexural strength and elastic modulus

- for final mechanical validation purposes print dog bones and bars if needed to comply with ASTM or ISO testing standards.