Fast and accurate Instructions for Use "IFU" for Inkjet printers

These fast and accurate Instructions for Use "IFU" can be used for printing our Inkjet resins and supports with most Inkjet printers:

3Dresyns Inkjet resins and supports have viscosities <20 mPas at 70ºC and <15 mPas at 80ºC for excellent inkjet printability in most inkjet printers.

Note: 3Dresyns for Multijet printers are supplied in two versions: liquid versions art room temperature for research and solid versions which melt >50ºC for daily production.

Standard settings for printing our Inkjet 3D resins ans supports in most Inkjet printers:

- Z layer or slice height or thickness is typically between 10-100 microns (0.01-0.1 mm). Lower or higher are also printable for most Inkjet 3D resins ans supports

- It is recommended to initially start printing the first calibration file 3Dtest1 with the standard settings of your Inkjet printer.

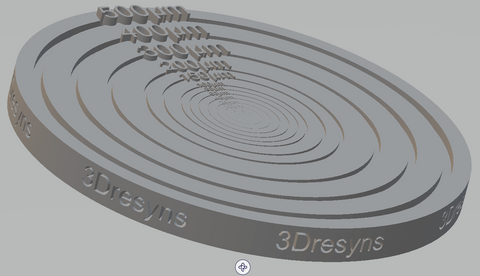

Start printing 3DTest1: the flat coin

- Printing the coin flat with the standard size as supplied is ideal for evaluating the inkjet printability and xy resolution

- The flat coin is printed without supports directly on the build platform. This first calibration test helps to identify the printability of a 2 mm thick coin of 25 mm of diameter, which can be printed for example with 20 z layers of 100 microns or with 40 z layers of 50 microns. This fast calibration file consumes very little resin and provides a fast proof of printability with the standard settings of your inkjet printer, as well as an indication of xy resolution since each concentric circle has certain width and depth

- The first concentric line starts with a width and depth of 500 microns (0.5 mm), the following ones have 400, 300, 200,150, 100, 80, 60, 40, 20, 10, 5, and 2 microns

- This fast calibration tests gives an indication of the xy resolution, since the thinnest observed circle will determine the xy resolution of the resin with your standard inkjet printing settings

- It there is any printing failure, reflected because the coin is not well printed or because it has poor resolution, it is required to

- Increase the light power in case the printed is too tender: under cured

- Decrease the light power in case the printed is too brittle: over cured

- Once you find the right settings for printing 3Dtest1 well, then you can use them for printing 3Dtest2: the flat coin with supports shown below:

Print 3DTest2: the flat coin with supports

- Once the flat coin is printed with goog resolution you may print 3Dtest2, the flat coin with supports. This second calibration file provides proof of printability of the coin with supports with the optimised settings used for printing the flat coin without any supports, as well as an indication of xyz resolution, since depending on the obtained printed thickness of the coin, the z resolution will be higher or lower. If for example, the thickness of the printed coin after removing the supports would be 2.1 mm, knowing that the theoretical thickness is 2.0 mm, the accuracy would be =(2.1-2.0)x100/2=5 % z accuracy

Evaluation the quality of the printed coin with supports

- Evaluate the xy resolution as shown before by reading the smallest width and depth of the printed concentric circles

- Measure the thickness of the coin vs the theoretical 3Dtest1 thickness, which as supplied has 2.0 mm, to quantify the z axis accuracy. This will permit you to calculate the % relative error in the z axis

- If you are not fully satisfied with the quality, or detail, or accuracy of your prints it is necessary to fine tune the 3D resin with our Fine Tuner FT1, and/or adjust your printing settings, e.g. by adjusting the light power. Depending on the origin of the print quality problem, different solutions are available.

Our inkjet3D resins come as standard ready to print with a broad range of Inkjet printers providing the light source wavelength is between 250-410 nm (higher wavelengths are also available)

Approximately 90 to 95% of our Inkjet resins and supports printability will come straight out of the bottle as supplied. You will be pleased to find that even then, the performance (printability and mechanical properties) far exceeds our competitor’s resins in most inkjet printers.

Our Inkjet 3Dresyns and supports can be fine tuned even further with our photoaccelerants (photocatalysts) for self-tuning their printing speed, resolution, precision, and dimensional accuracy with different Inkjet printer types and printing settings, such as specific light power and z layer thickness.

Free samples of our photoaccelerant (photocatalyst) Fine Tuner FT1 will be sent for self-tuning if necessary and upon request to provide maximum control and balance of printing speed, xyz resolution, precision, and dimensional accuracy.

3Dresyns is the first and only company up to date that supplies:

- Fine Tuners for custom control of printing speed and dimensional accuracy

- Scientific Instructions for Use IFU and calibration files (flat coin with supports) for measuring and optimising the dimensional accuracy in the 3 dimensions, the x, y, and z axis.

Alternative calibration files only take into account the xy resolution, ignoring that any 3D object requires the measurement of the dimensional accuracy in the 3 spatial dimensions.

For more info read: The difference among resolution, precision, and dimensional accuracy

Printing speed can be custom adjusted by fine tuning our 3D resins and supports to most Inkjet printers with:

- Fine Tuner FT1 is our favourite photo accelerant (photocatalyst) recommended for increasing the cure speed of our Inkjet resins and supports in Inkjet printers working with UV/Visible light wavelengths up to 410 nm (250-410 nm range)

- If you are printing opaque colored 3Dresyns with very low power Inkjet 3D printers our Fine Tuner FT2 can also be used

- If you are printing biocompatible 3Dresyns Fine Tuner FT2P is recommended due to its ultra high hidrophobicity and extremely low water solubility and extractability

- Fine Tuner FT4 Bio HP and Fine Tuner FT4 Bio are our 100% biocompatible photo accelerants (photocatalysts) specially recommended for increasing the cure speed of our 3Dresyns in printers working with Ultraviolet and Visible lights from 250 nm up to 500 nm: including the far, medium and near UV range, as well as the visible range (daylight), with the benefit of not having any safety issues. Both are ideal for printing biocompatible systems since are ultra safe, not cytotoxic and 100% biocompatible (without any warning labels/ pictograms)

- If you need ultra safe Water Soluble WS or HydroPhillic HP 100% biocompatible and bio-based photo accelerants (photocatalysts) discover: Fine Tuner FT5 Bio WS

- It is recommended the use of Fine Tuners FT in steps of 0.5% to increase gradually printing speed. Avoid over dosage to avoid overcure of the Inkjet resin (and/or support resin) beyond limits/specifications, resulting in excessive brittleness and yellowing

The following figure clearly shows the difference among resolution, precision, and dimensional accuracy:

Examples of measurements with low and high accuracy, precision, and resolution. The center represents the true value and each yellow dot is a measurement sample (Source: How to Calculate with Uncertainty)

In our case, resolution refers to the smallest concentric circle line printed on the surface of the printed coin and to the printed micrage in relief (see image below), since each circle line has engraved (and written in stereo the micrage) its width and depth in decreasing order from 500 to 2 microns.

You are welcome to contact us and order more products and services by email at: info@3dresyns.com