Detailed guidelines to select the right 3D resin for your needs

How to choose the right 3D printing material?

- Most commercial 3D resins exhibit poor mechanical properties, such as poor toughness and mechanical strength. They contain low viscosity monomers, which are fragile like eggshells and responsible for skin irritancy and other more severe hazards

Let us help you find the right resin for your needs.

Detailed guidelines to select the right 3D resin for your needs in sequential steps:

- If you are after basic "me too cheaper" but safe 3D resins for fast modelling and prototyping order our basic 3D resins for conceptual design or competitor´s low cost resins if safety is not a concern or priority

- If you are after basic eco friendly and bio based 3D resins order our 3D resins for fast modelling and prototyping

- If you want ultra tough and durable functional engineering materials order our 3Dresyns "like" best functional engineering plastics

Select your resin by a key physical property such as Shore hardness

What is the Shore hardness of a material? how is it measured?

- The Shore hardness is measured with a durometer, which is an affordable device for measuring the hardness of a material, typically of polymers, elastomers, and rubber-like materials

- Higher numbers on the scale indicate a greater resistance to indentation and thus harder materials. Lower numbers indicate less resistance and softer materials

There are several scales of durometer, used for measuring the hardness of materials. The most common are the type D, A and OO Shore hardness scales:

- The Shore D hardness scale measures the hardness of hard rubbers, semi-hard and hard plastics: hard 3D resins

- The Shore A hardness scale measures the hardness of flexible rubbers that range in hardness from very soft to soft to medium soft rubbers: soft 3D resins

- The Shore O (and OO) hardness scale measures ultra soft rubbers and gels that are extremely soft: ultra soft resins

If you do not have a Shore durometer you can get one for 30 Euro in Amazon.

Get a D, A, or O scale durometer depending on the type of hardness materials you want to work with.

Identify the ideal Shore hardness of your specific application

Search and find the right 3Dresyn among our thousands of 3D resins by simple key properties:

- Click on SEARCH and write the Shore hardness of your preliminar choice eg Shore hardness D80 or directly D80

- All our 3Dresyns with their Shore values will appear in your search (letter D,A, or O followed by 2 digits without any space e.g. D90)

- For each Shore hardness materials can be more or less rigid and have higher or lower overall mechanical strength

- Identify the ideal rigidity by Young´s modulus and Strength of your 3D resin

The flexibility and rigidity of a material can be identified by its Young´s or Elastic modulus: the higher its value the higher the rigidity:

- For each rigidity or Young´s modulus value materials can have higher or lower overall mechanical strength

- Do not waste time, print ultra resistant functional engineering materials with our unique 3Dresyns "like" best functional engineering plastics

Basic information about Young´s modulus values:

- Ultra rigid 3D resins have Young´s modulus >3000 MPa

- Rigid 3D resins have Young´s modulus >2000 MPa

- Semirigid and semiflexible 3D resins have Young´s modulus 1000-2000 MPa, typically they are rigid at thickness >2-3 mm and semi flexible at thickness <2-3 mm

- Flexible 3D resins have Young´s modulus <1000 MPa, typically they are rigid at thickness >3-4 mm and flexible at thickness <3-4 mm

- Elastic 3D resins have Young´s modulus <1-10 MPa, typically they are flexible even at very high thickness

Basic information about mechanical strength values:

- Ultra rigid 3D resins break without significant deformation and tend to be fragile due to their excessive rigidity

- Ultra tough and rigid 3D resins such as 3Dresyn PEEK-like can reach >100-130 MPa in flexural strength. They are very resistant, breaking with minor deformation

- Tough and semi rigid 3D resins, such as 3Dresyn Nylon-like can reach incredible relative flexural strengths >40-80 MPa and can be bent upon relatively high pressure without breaking at less than 2 mm thickness

- Semi-flexible 3D resins with flexural strengths<50 MPa are typically deformable, without breaking, upon pressure at less than 3 mm thickness

- Flexible and elastic 3D resins naturally have low flexural strength <1-10 MPa and break relatively easily

Alternative SEARCH by keywords:

- Click on SEARCH and add to your chosen Shore other relevant keywords relevant to your product of interest. Examples:

By product type keywords:

- 3Dresyn for searching our all our 3D resins collections

- Fine Tuner FT for searching our photo accelerants (photocatalysts)

- Fine Tuner LB for searching our resolution-ers or resolution increasers

- 3D-ADD for searching our functional additives such as:

- Rigidity modifiers, matting and opaquer additives, non stick and resistance additives, conductive additives, adhesion promoters and primers, crosslinkers, degradation promoters and testers, uv radiation protection, densifiers, flame and fire retardants, radio opaque agents, magnetic agents, polishing pastes, etc...

- Thinner 3Dresyn for searching our 3D diluents

- Cleaning products for searching our cleaning fluids, cure testers, purification kits and detoxifiers

- Wax related products

- Services for searching our consulting services for 3D resin customisation services and full 3D printing systems solutions

By property keywords:

- functional

- high deflection temperature or HDT

- temperature resistant

- rigid

- tough

- flexible

- elastic

- super elastic

- soft

- biocompatible

- safe

- monomer free

- water soluble

- solvent soluble

- hydrophobic

- hydrophillic

- conductive

- chemical resistant

- bio for bio based

- cast, castable or casting

- silicone

- ESD

- ferroelectric

- magnetic

- sintering

- insulation

- refractive

- wear

- slip/anti slip

- fire retardant

- neutron absorber

- anti sedimentation

- matt

- opaque

- radio opaque

- non yellowing

By color keywords:

- Search for your needed color name: 3Dresyns Colors collection

By application keywords:

- engineering

- dental

- aligner

- biomedical and biocompatible

- jewelry

- otoplastic

- microfluidic

- printing plate

- hydrogel

- ophthalmic

- scaffold

- durable mold

- sacrificial mold

- security

- adhesive

By printing or manufacturing technique keywords:

- SLA for Stereolithography

- IJ for Inkjet

- VAM for Volumetric Additive Manufacturing

- VLM for Viscous Lithography Manufacturing

- HM for Hot lithography

- Casting

- Injection

- CIM for Ceramic Injection Molding

- MIM for Metal Injection Molding

By other keywords:

By your own. Be creative and user your own combination of keywords for searching the right 3Dresyn for your unmet needs: SEARCH

Key selection guidelines for selecting any type of 3D resin:

- Acknowledge that any material may appear more or less rigid or flexible depending on their thickness

- Metal foils are flexible but thick metal parts are rigid

- Soft rubber films are flexible but very thick parts are rigid

- Each material appears flexible up to certain thickness at which starts to appear more and more rigid while increasing its thickness

- Rigid materials with rod shapes do bend upon pressure below certain thickness

- Flexible materials with rod shapes do not bend upon pressure above certain thickness

- Identify the smallest and thinnest part or "minimum feature size" of your 3D printable object.

- Identify the minimum required relative rigidity of the minimum feature size

- Thicker feature sizes will appear more rigid thanks to their thicker sizes

- Avoid selecting too rigid materials for your application needs since excessive rigidity results in reduced toughness or excessive fragility, such as "eggshell-like" materials: glass, ceramics, etc,..which are rigid but fragile!

- Avoid selecting too flexible materials for your application needs since excessive flexibility results in reduced toughness, flexural strength and tear resistance, such as too flexible and easy to break elastomers

- For rigid materials select the minimum required rigidity of the smallest feature size of your prints to maximise mechanical strength since thicker parts will appear more rigid

- For flexible materials select the maximum and the minimum required flexibility of the smallest and biggest feature size of your prints to balance or average both to satisfy your needs

Typical experimental findings and thumb rules by decreasing Shore values. From Shore D90 downwards:

- The higher the Shore D (above D90 range) the higher the rigidity (Young´s modulus) but due to excessive rigidity, mechanical properties such as flexural strength and impact resistance can decrease

- The higher the Shore D (D70-D90 range) the higher the rigidity (Young´s modulus) and mechanical properties of most rigid materials

- In the Shore D50-D80 range, sometimes softer D60 resins can be more rigid and mechanically resistant that harder Shore D80 resins, consequently the natural hardness-rigidity-strength direct proportion "formula" can be reversed. This happens with some of our unique Engineering 3D resins which contain highly resilient bio based building blocks, which are ideal for designing eco friendly ultra resistant functional engineering bio materials!

- From Shore D50 downwards materials increase their flexibility but decrease their mechanical strength. Choose our NextGen 3dresyns for engineering or our Bioflex 3Dresyns for biocompatible flexible materials

- The higher the Shore A the higher the mechanical properties for most flexible and elastic materials: choose as high as possible Shore A resins for maximum overall mechanical performance

- From Shore A50 to A10 materials become very soft and typically are elastic and prone to have poor mechanical strength. Choose our elastic NextGen 3Dresyns for engineering or our Bioflex 3Dresyns and Bioelastic 3Dresyns for biocompatible elastic materials

Key selection guidelines for selecting engineering functional materials:

- Our Enginering 3Dresyns "like" engineering materials are ideal for Engineering functional applications where ultra high durability and mechanical performance are required. These 3Dresyns contain bioplastics from renewable resources and are more environmentally friendly than petroleum based plastics.

- Our Enginering 3Dresyns "like" best high performance engineering plastics are supplied with access to all our colors and functionalities. They are supplied with a relatively low or high viscosity for even increased overall mechanical performance:

- High Viscosity versions exhibit increased mechanical properties and are ideal for printers having heating systems for printing at >25ºC

- Low Viscosity versions exhibit relatively lower, but still quite high, mechanical properties and are ideal for printers without any heating systems for printing at <25ºC and >25ºC

- Learn more about the Benefits of printing with heated printers

Other key selection guidelines for selecting "green" biocompatible materials:

- Both, our Monomer Based MB and Monomer Free MF 3D resins exhibit similar strength for each Shore value

- Monomer free MF versions do not contain any monomers as supplied, consequently the risk of causing skin irritation is minimised

Basic & simple screening of 3D resins properties for selecting the right 3D resin before printing your final prints:

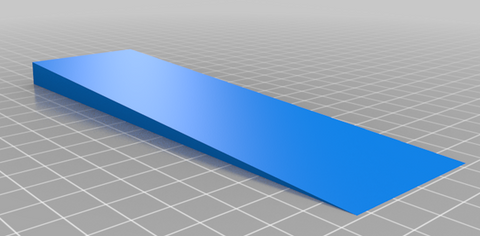

- Print directly a wedge with your chosen 3D resin

- Adjust the wedge size to the total surface of your prints on the build platform

- Print the wedge directly on the build platform. If it breaks during its separation with the spatula due to excessive adhesion to the platform, then print it with supports or sidewards to facilitate its removal

- Use the printed wedge to screen the peeling or separation force, the flexibility/rigidity as well as the fracture resistance of the material

- Position the wedge vertically and force it sidewards gently and firmly to measure the thickness at which the wedge does not deform or bend at all. This value in mm will give an indication of the thickness threshold at which the material becomes rigid. Below this thickness threshold the material is flexible

- Position again the wedge vertically and force it sidewards strongly and firmly until it breaks to measure the maximum thickness at which the tip of the wedge breaks. This value in mm will give an indication of the toughness of the material. The lower the thickness of the remaining wedge the tougher the material!!

- Design a thinner or thicker, a shorter or longer wedge depending on your needs, which will depend on the relative size of your printed parts

- Relatively thinner and longer wegdes are ideal for small size works

- Relatively thicker and shorter wedges are good enough for large size works

- Relatively longer wedges help to identify smaller differences in rigidity/flexibility and in toughness since the maximum thickness, at which the tip of the wedge deforms and breaks upon pressure, can be measured with more precision

- Print a wedge horizontally, without supports in your printer

- Depending on your initial results, test or not a more rigid or flexible resin, taking into account your required flexural strength and elastic modulus

- For final mechanical validation purposes print dog bones and bars if needed to comply with ASTM or ISO testing standards

Discover our consulting services:

Click on these links for our full printing consulting and our 3D resin customisation services:

- Soluble sacrificial resins

- Resins for printing injection molds

- Biocompatible resins for biomedicine

- Orthodontic & dental resins

- Silicone resins

- Biodegradable resins

- Microfluidic 3D resins

- UV nanoimprint lithography

- Resins for ceramics and metals

- Resins for scaffolds

- Conductive resins for electronics

- Resins for bio sensors

- Reinforced composite resins

- Viscous & hot lithography resins

- Resins for security systems

- Piezoelectric & ferroelectric resins

- 4D reversible resins

- 3D resins for printing plates

- Two photon polymerization

- Resins for multiwavelength printing

- Resins with variable composition

- Resins for VAM

- Metamaterials

- 90% of received emails are answered in less than 1 hour

- 100% of received emails are answered in less than 24 hours